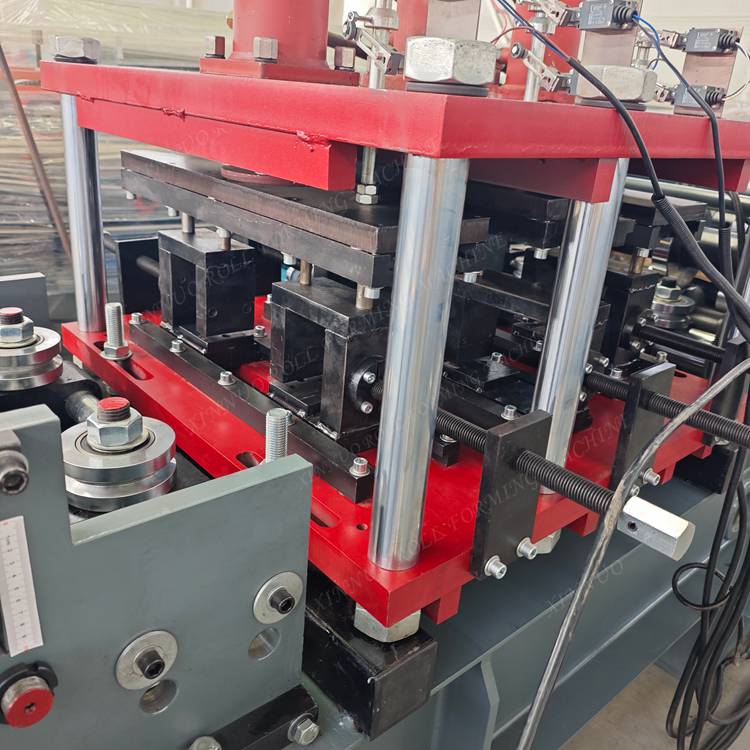

The C-shaped steel purlin forming machine adopts advanced automated rolling technology.

Through the precision-designed roller set and intelligent control system, it can quickly convert rolled metal sheets into high-precision C-shaped steel products.

The equipment supports one-click parameter adjustment.

The operator only needs to enter the required specifications on the touch interface to automatically complete the precise setting of parameters such as purlin height, width, and curling size. From unwinding, leveling, rolling, cutting to finished product collection, the entire production process is fully automated, effectively reducing manual intervention and controlling production errors within the millimeter level.

Thanks to the modular design and intelligent monitoring system, the production capacity of a single forming machine can reach more than 100 meters per hour, and it can achieve rapid switching of products of different specifications, significantly improving production efficiency and material utilization.

In addition, the equipment is also equipped with fault warning, energy consumption monitoring and other functions to further reduce maintenance costs and safety risks.

Whether it is large-scale standardized production or personalized customization needs, the C-shaped steel purlin forming machine can promote the steel structure construction industry to continue to move towards intelligence and efficiency with stable and reliable performance.

| C-shaped steel specifications | Adjustment width (80-300) mm , height (40-80) mm |

| Main machine weight | About 15 tons |

| Length tolerance | 5 meters ±1.0 |

| Main machine volume | 12.5 meters long, 1.9 meters wide, and 1.9 meters high |

| Structure thickness | 30 mm Steel Plate |