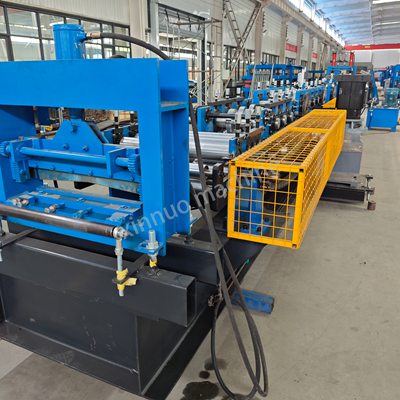

Under frame 400 mm H Steel

Roller material Cr12

Shaft diameter 80mm

Transfer method 2 inch chain drive

Structure"Independent cast iron archway.

more stable and very strong."

Main motor power Hydraulic motor

Cutter material Cr12Mov

Purlin roll-forming machines utilize cold-bending technology to form metal sheets into C-, Z-, and U-shaped purlins. These machines are widely used in roof and wall support systems for steel structures.

The machine operates by continuously shaping the purlins through multiple rolls. Coils of galvanized steel, color-coated steel sheets, and other raw materials (typically 0.8-3mm thick) are steadily conveyed through a feeder rack. After being aligned by guides, they enter a series of 15-25 rollers arranged in sequence. Each set of rollers gradually bends the sheet material at a preset angle, gradually forming a standardized cross-sectional shape. High-temperature heating is not required throughout the entire process, preserving the sheet material's inherent strength and toughness.

The machine utilizes a fully automated control system. From coil unwinding and roll-forming to cut-to-length (with an accuracy of ±1mm), and stacking of finished products, all operations are precisely controlled by a PLC system. The machine boasts a continuous processing speed of 10-30 meters per minute, with a single-shift production capacity exceeding 15,000 meters. Core components offer outstanding performance: the forming rollers are made of high-hardness alloy steel (HRC55 and above), ensuring long-term machining accuracy. The hydraulic flying saw cutting system enables uninterrupted cutting without compromising production continuity. Rapid die changes (30-60 minutes) allow for the production of purlins of varying specifications, meeting customized requirements for widths from 100-300mm and lengths from 1-12 meters.

Compared to traditional processing methods, this system offers significant advantages: material utilization rates exceed 95%, reducing waste; cold bending consumes 60% less energy than hot rolling; and the finished product's cross-sectional dimensional tolerance is ≤±0.5mm, with a straightness tolerance of ≤1mm/m, ensuring precise installation. It has become a key production equipment for steel structures such as industrial plants, warehouses, and stadiums, driving the trend towards lightweight and modular construction.