Under frame 400 mm H Steel

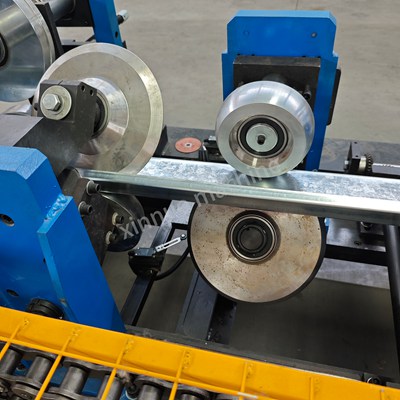

Roller material Cr12

Shaft diameter 80mm

Transfer method 2 inch chain drive

Structure"Independent cast iron archway.

more stable and very strong."

Main motor power Hydraulic motor

Cutter material Cr12Mov

The purlin roll-forming machine features a seamless and highly automated production process, primarily consisting of the following steps:

First, raw material preparation involves securing coiled metal sheets (such as galvanized or cold-rolled steel) on a feed rack. A hydraulic tensioner ensures the coils are secure and prevents deviation during transport.

Next, the sheet enters the guide and straightening stage, where the sheet is conveyed along a guide mechanism. Straightening wheels and stop plates adjust the sheet's position in real time, eliminating any slight bends or deviations in the raw material and ensuring subsequent processing accuracy.

In the core roll-forming process, the sheet enters a set of 15-25 rollers arranged in a specific sequence. Each set of rollers progressively rolls and shapes the sheet according to preset parameters, gradually bending the flat sheet into the desired cross-section, such as a C-shaped or Z-shaped section. The entire process is completed at room temperature, preserving the steel's mechanical properties.

The formed continuous profile enters the cut-to-length stage, where a hydraulically driven flying saw rapidly cuts the sheet to the preset length. The cutting speed is synchronized with the conveyor speed, ensuring a smooth cut and a length tolerance within ±1mm.

Finally, the finished product is output. The cut purlins are transported via a conveyor rack to a collection area where they are automatically stacked into stacks, completing the entire production process. A PLC control system coordinates all steps throughout the process, enabling continuous, automated production from raw material to finished product, eliminating the need for manual intervention at key steps.