C-purlin roll forming machines are core profile processing equipment in steel structure engineering. They are specifically designed to process metal coils (such as galvanized steel and cold-rolled steel) into standardized C-shaped purlins, and are widely used in factories, warehouses, photovoltaic supports, and light steel structure housing.

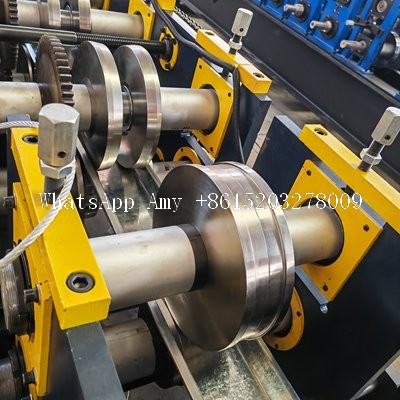

The equipment employs a continuous roll forming process, operating fully automatically: after unwinding and leveling, the metal coil is progressively bent and shaped by multiple sets of precisely calibrated rollers, and then precisely cut by a length-cutting system, ultimately producing C-shaped purlins with uniform dimensions and smooth surfaces. Its core advantages are significant: high forming accuracy, relying on an intelligent control system to control the roll pressure and speed, with errors controlled to the millimeter level; high production efficiency, with a single production line achieving a processing speed of several meters per minute, far exceeding traditional manual processing; and low material loss, with an optimized roll path reducing waste and achieving a raw material utilization rate of over 95%.

Meanwhile, the equipment is easy to operate, equipped with a user-friendly touch interface, allowing even beginners to quickly get started; it boasts strong operational stability, employing high-quality alloy steel rollers and a thickened frame, making it wear-resistant and damage-resistant, ensuring continuous and trouble-free operation; it has a wide range of applications, adapting to different purlin processing needs (thickness 1.5-4mm, height 100-300mm) by adjusting roller parameters. Furthermore, the equipment operates with low noise and low energy consumption, meeting environmental protection requirements and helping companies reduce production costs, making it a key piece of equipment for improving efficiency and ensuring project quality in modern steel structure processing.