The C-purlin rolling forming machine is the core equipment used to produce C-type purlins in the construction industry.

The C-type purlin has a C-shaped cross-section and is an important supporting component of the roof and wall structure. It is widely used in industrial plants, warehouses, steel-structured houses and other construction scenes.

| Raw material hardness | G350-G450 |

| Raw Material Thickness | 1.5-3.0 mm 2.0-3.0mm |

| Product (C/U) size |

100mm/200mm/255mm 50mm/76mm 19mm |

| Sheet cutting length | Adjustable |

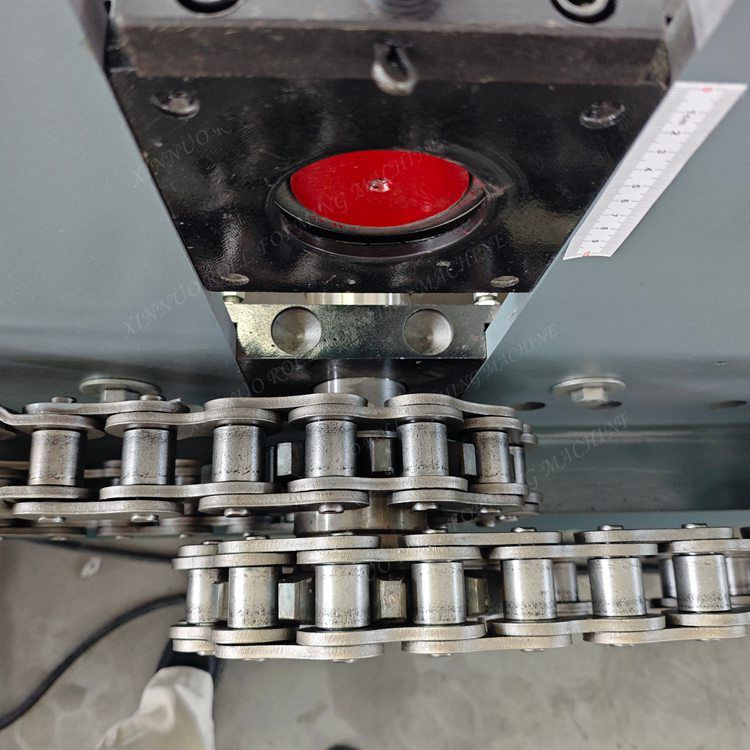

| Roller material | CR12 |

The equipment adopts an automated rolling forming process. Through multiple sets of rollers, the metal sheet is progressively cold-bent in sequence, and the rolled sheet raw materials can be quickly and accurately processed into C-type purlins that meet the design requirements.

The equipment is equipped with an advanced CNC system, which supports flexible setting and adjustment of parameters such as the length, specification, and curvature of the purlin to meet the diverse needs of different construction projects.

At the same time, the rolling forming process is continuous and efficient, with fast production speed and stable forming quality, which can effectively reduce material loss and improve production efficiency.

In addition, some high-end models also integrate functions such as automatic feeding, cutting, and stacking to achieve full-process automated operation, greatly reducing labor costs. It is an indispensable and efficient equipment in the production of modern steel structure buildings.