Under frame 400 mm H Steel

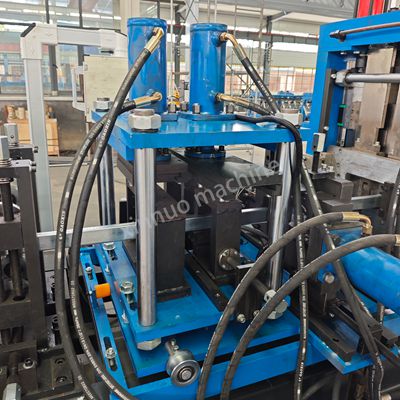

Roller material Cr12

Shaft diameter 80mm

Transfer method 2 inch chain drive

Structure "Independent cast iron archway.

more stable and very strong."

Main motor power Hydraulic motor

Cutter material Cr12Mov

The purlin roll-forming machine is a high-precision automated device designed specifically for cold roll forming. Its core function is to continuously roll galvanized steel, color-coated steel, cold-rolled steel, and other metal sheets through multiple sets of rollers into purlins with specific cross-sections, such as C-, Z-, and U-shaped. These purlins, critical load-bearing components of steel structure roof and wall support systems, are widely used in modern architecture.

Based on cold roll forming technology, the machine uses 15-25 sets of rollers arranged in a specific sequence to progressively shape the sheet metal without preheating the metal. Each set of rollers is responsible for a specific bend angle and curvature. After multiple steps, the purlins are formed to meet standard cross-sections while preserving the sheet metal's original mechanical properties. The entire process is fully automated, from coil unwinding, guide correction, roll forming, to cut-to-length cutting and finished product stacking. Human intervention is eliminated at critical stages, and the PLC control system precisely sets parameters to ensure stable production.

Core components include a hydraulically tensioned unwinder to ensure stable coil conveying; a guide device with straightening wheels to correct sheet deviation in real time; a forming unit comprised of high-strength alloy rollers (hardness exceeding HRC55) to ensure long-term processing accuracy; a hydraulic flying saw cutting system to achieve ±1mm cutting accuracy; and a touchscreen PLC control system with parameter setting and fault warning.

This equipment offers significant advantages: exceptional energy efficiency, with energy consumption 60% lower than hot rolling processes; high production efficiency, with a continuous speed of 10-30 meters per minute and a single-shift capacity of 15,000 meters; exceptional precision, with a cross-sectional dimensional error of ±0.5mm and a straightness error of ≤1mm/m; a material utilization rate exceeding 95%, reducing waste; and exceptional flexibility, with die changes completed in 30-60 minutes. It accommodates sheet metal 0.8-3mm thick and 100-300mm wide, and can produce purlins 1-12 meters long.

It is widely used in industrial plants, warehouses, gymnasiums, steel structure office buildings and other scenes. The purlins it produces have the characteristics of strong load-bearing capacity, light weight and easy installation. It promotes the development of steel structure buildings towards lightweight and modularization, provides key support for the popularization of green buildings, and is the core equipment of modern building industrialization.