Under frame 400 mm H Steel

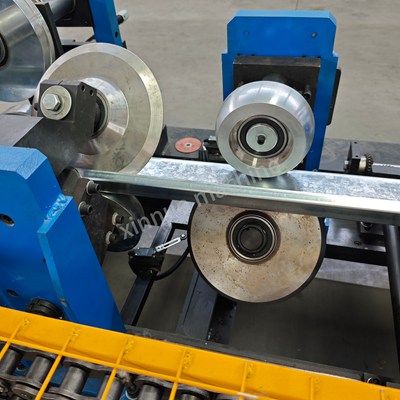

Roller material GCR15+Cr12

Shaft diameter 80mm

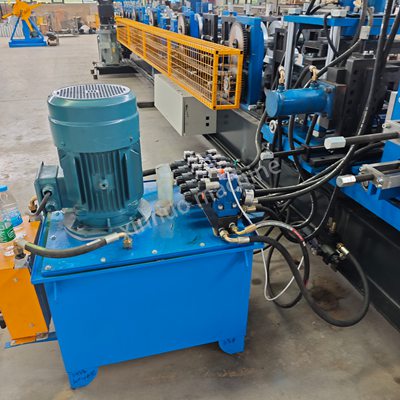

Transfer method 2 inch chain drive

Structure "Independent cast iron archway.

more stable and very strong."

Main motor power Hydraulic motor

Cutter material Cr12Mov

The Purlin Roll Forming Machine is an automated device specifically designed for cold roll forming. It is primarily used to form purlins with specific cross-sectional shapes from metal sheets (such as galvanized steel and color-coated steel) through continuous rolling. These purlins are widely used in roof and wall support systems for steel structures.

I. Core Functions and Operating Principles

Cold Roll Forming Process

Without heating the sheet, multiple sets of continuously arranged roller dies gradually apply pressure to the metal coil (or sheet), causing plastic deformation, ultimately forming the purlin cross-section (such as C-section, Z-section, or U-section) that meets the design requirements.

Automated Process

From raw material loading and feeding, roll forming, to cut-to-length cutting and finished product delivery, the entire process is automated, reducing manual intervention and improving production efficiency.

II. Main Types and Applications

Based on the cross-sectional shape of the purlins being processed, common types include:

C-shaped steel purlin machines: Process purlins with a "C" cross-section, suitable for small and medium-span steel structures, and easy to install.

Z-shaped steel purlin machines: Process purlins with a "Z" cross-section, offering increased strength and suitability for large-span buildings. Overlapping improves overall stability.

Multi-functional purlin machines: By replacing molds, they can switch between C-shaped and Z-shaped cross-sections, offering high flexibility and adapting to diverse specifications.

III. Equipment Structure

Unloading rack: Holds metal coils and ensures stable raw material delivery.

Guide: Corrects sheet material delivery direction to prevent deviation that could affect forming accuracy.

Roller forming unit: The core component, consisting of multiple sets of roller dies, gradually bends the sheet material according to the purlin cross-section design.

Cut-off unit: Uses hydraulic or pneumatic cutting to precisely cut the formed purlins to the set length. Control System: PLC programming allows for customizable parameters such as purlin length and thickness, enabling automated production and fault warning.

IV. Advantages and Features

High Efficiency and Energy Saving: Cold-bending requires no heating, resulting in low energy consumption and a continuous production speed of 10-30 meters per minute, far exceeding traditional welding or stamping processes.

High Precision: The precision-machined roller molds ensure that the dimensional tolerance of the formed purlins is controlled within ±0.5mm, ensuring installation compatibility.

High Material Utilization: Compared to traditional cutting and welding processes, virtually no waste is generated, saving metal material costs.

High Flexibility: By replacing molds and adjusting parameters, purlins of varying thicknesses (typically 0.8-3mm) and specifications can be processed to meet diverse building requirements.

V. Application Areas

This product is widely used in roof and wall support systems for industrial plants, warehouses, gymnasiums, steel-structured office buildings, and other structures. It is an indispensable key processing equipment in steel structures. The purlins it produces combine strong load-bearing capacity with light weight and excellent seismic performance, promoting the lightweight and modular development of modern steel structures.