Under frame 400 mm H Steel

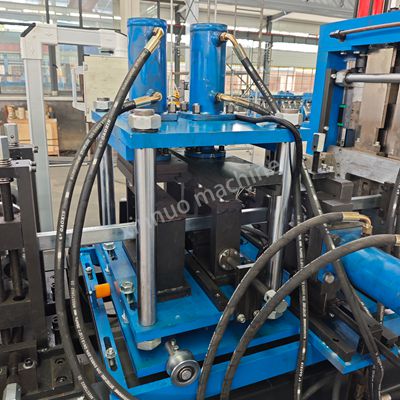

Roller material Cr12

Shaft diameter 80mm

Transfer method 2 inch chain drive

Structure"Independent cast iron archway.

more stable and very strong."

Main motor power Hydraulic motor

Cutter material Cr12Mov

The purlin roll-forming line consists of equipment for unwinding, guide correction, roll forming, cut-to-length cutting, and finished product stacking.

Interconnected by a PLC system, it achieves fully automated continuous production.

The unwinding mechanism provides stable material feeding, guide correction eliminates sheet deviation, 15-25 sets of rollers progressively shape the material, and a flying saw provides precise cutting (with an accuracy of ±1mm).

The entire process requires no human intervention, with speeds reaching 10-30 meters per minute and a single-shift production capacity exceeding 15,000 meters.

The factory offers significant advantages: First, high efficiency, rapid response to large-scale orders, and shortened delivery cycles. Second, excellent precision, with purlin cross-sectional tolerances within ±0.5mm, straightness ≤1mm/m, and stable mechanical properties.

Third, low cost, with material utilization exceeding 95%, 60% energy savings compared to hot rolling, and low labor costs. Fourth, high flexibility, enabling conversions to C/Z/U shapes and various specifications within 30-60 minutes. Fifth, comprehensive service, including installation and commissioning, training, and after-sales service, and strict quality inspection, ensures stable production for customers. Custom engineering can precisely adapt to the unique needs of a project.

Purlin specifications and production plans can be customized based on the spans, loads, and environments of different buildings, avoiding wasted resources. This improves construction efficiency. Customized purlins require no secondary processing and can be assembled directly and quickly. Material supply is tailored to the construction schedule, minimizing project delays. Furthermore, the customization process rigorously controls materials, processes, and testing.

For example, weather-resistant purlins are customized for corrosive environments to ensure structural stability and safety. Furthermore, precisely matching requirements can reduce losses due to excess or insufficient product, optimize resource allocation, reduce transportation, storage, and ongoing maintenance costs, and enhance project economics.